While most waste materials are not electrically conductive under normal conditions, they become conductive when heated to high temperatures, particularly in a molten state. Our technology harnesses this property by passing a current between electrodes, generating Joule heat to efficiently heat and treat molten waste. This cutting-edge method ensures effective and sustainable waste management.

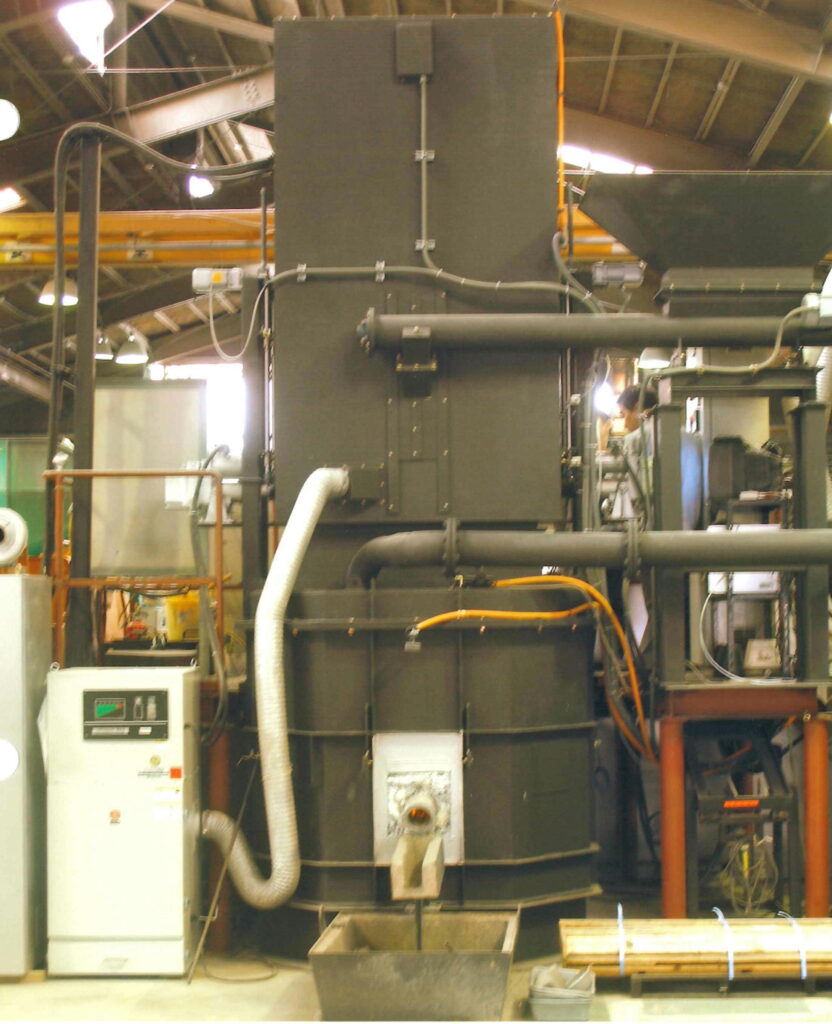

Furnace Main Body

| Daily Capacity | Our melting furnaces are available in capacities ranging from 5 tons to 30 tons. For larger requirements, custom-built furnaces can be manufactured to meet your specific needs. |

| Treatable Waste | Our system is designed to handle various waste materials, including incineration ash, sludge, PCBs, asbestos, medical waste, shredder dust, and low-level radioactive waste, etc. |

| Byproducts | Our process allows for glass-solidified slag to be crushed and recycled. Additionally, metals are separated respectively, enabling efficient recycling of valuable materials. |

Melting Furnace and Electrodes

| Internal Temperature | 1100°C to 2000°C (temperature rise in a short time: approximately 1 hour) PCBs require temperatures above 1100°C, and asbestos requires temperatures above 1500°C. The temperature can be set freely depending on the waste treatment temperature and the furnace’s heat resistance. |

| Movement | Variable control of electrodes and automatic current regulation enable optimal temperature settings and energy efficiency. |

| Environmental Impact | Our process is non-combustive, eliminating the need for oxygen and significantly reducing CO2 emissions. |